Products

As the world’s fastest tire mold manufacturer, we are engineered to perform.

At King Machine, we are built to a higher standard. We help you meet production goals, stay ahead of demand, and minimize downtime.

And every tire mold is backed by 75 years of American manufacturing.

We bring speed, precision, and partnership to everything we do.

Don’t see what you need on this list? Reach out to us—we can handle it.

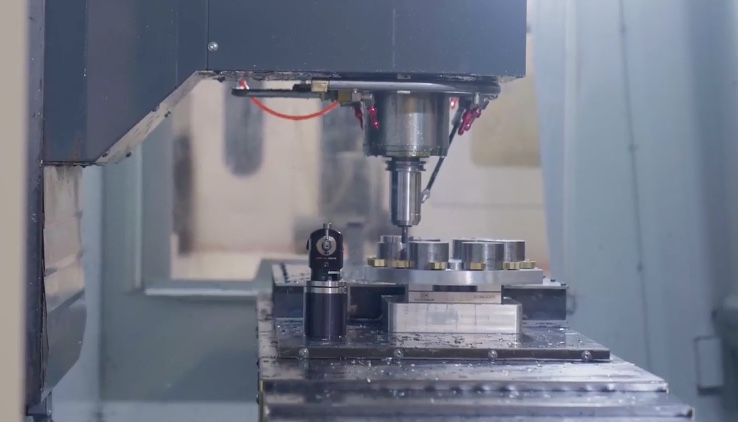

Our current capabilities include:

- World’s fastest tire mold manufacturing

- Models

- Aluminum tread ring foundry

- Sidewall plate machining and engraving

- Treaded/lugged sidewall design

- High-Contrast Laser Texturing

- Bead rings

- Puzzle/ventless mold manufacturing

- Steel mold backs

- 5-axis modeling, machining, and engraving

- Non-radial tread segment ends

King Machine’s Hypermold Service

The ultimate in speed, agility, and service, to ensure you

hit all your production goals.

For us, speed isn’t just about getting it done fast—it’s about getting it done right.

Our quick-service, fast-track, expedited tire mold program delivers results faster than any other tire manufacturer, without sacrificing precision or consistency.

Have a challenge?

Up against a deadline?

Put our speed to work for you.

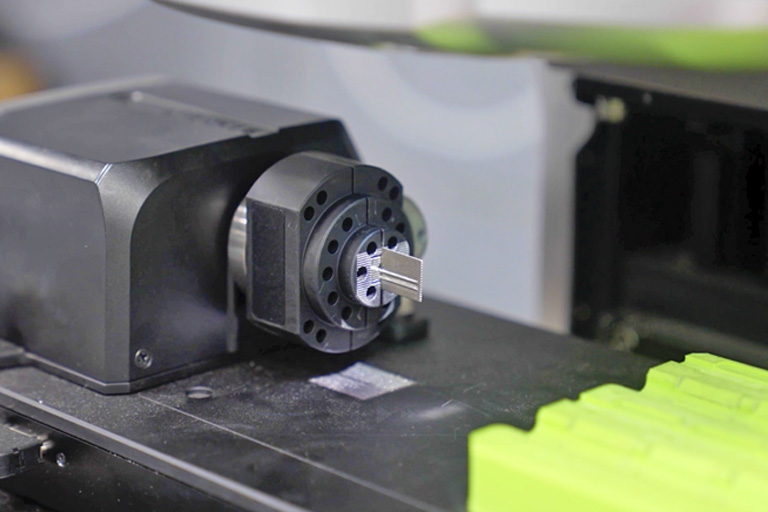

King Machine’s Additive Manufacturing Division: S-Werx

We specialize in the production of new tire molds and components.

At King Machine, we are always chasing perfection, offering bold agility and a desire to push the limits. And we speak your language—our team is technically precise, we excel at problem-solving, and we pivot fast. When challenges come up, we’re on it. No excuses, no delays.

We recently vertically-integrated our production process, bringing S-Werx to life. Our new additive manufacturing division focuses on sipe and model production. This has allowed us to bring industry-leading precision, speed, and quality to our tire mold production.

- Faster turnaround with in-house technology that streamlines production and boosts mold quality

- Handles high complexity without impacting lead times

- Limitless possibilities — if customers can imagine it, we can print it

- Precision and reliability built into every stage of the process

Sidewall Production

Our proprietary software and engraving technology deliver what no one else can—bold tread-to-sidewall designs with the speed and capacity of today’s off-road market demands.

King Machine specializes in advanced sidewall engraving, seamlessly carrying tread patterns into the sidewall for bold, off-road tire designs. Our unique expertise and technology give customers greater design freedom and unmatched manufacturing capacity compared to competitors.